PC strand for construction

?What Is Prestressed Strand and Why Is It Used in Construction

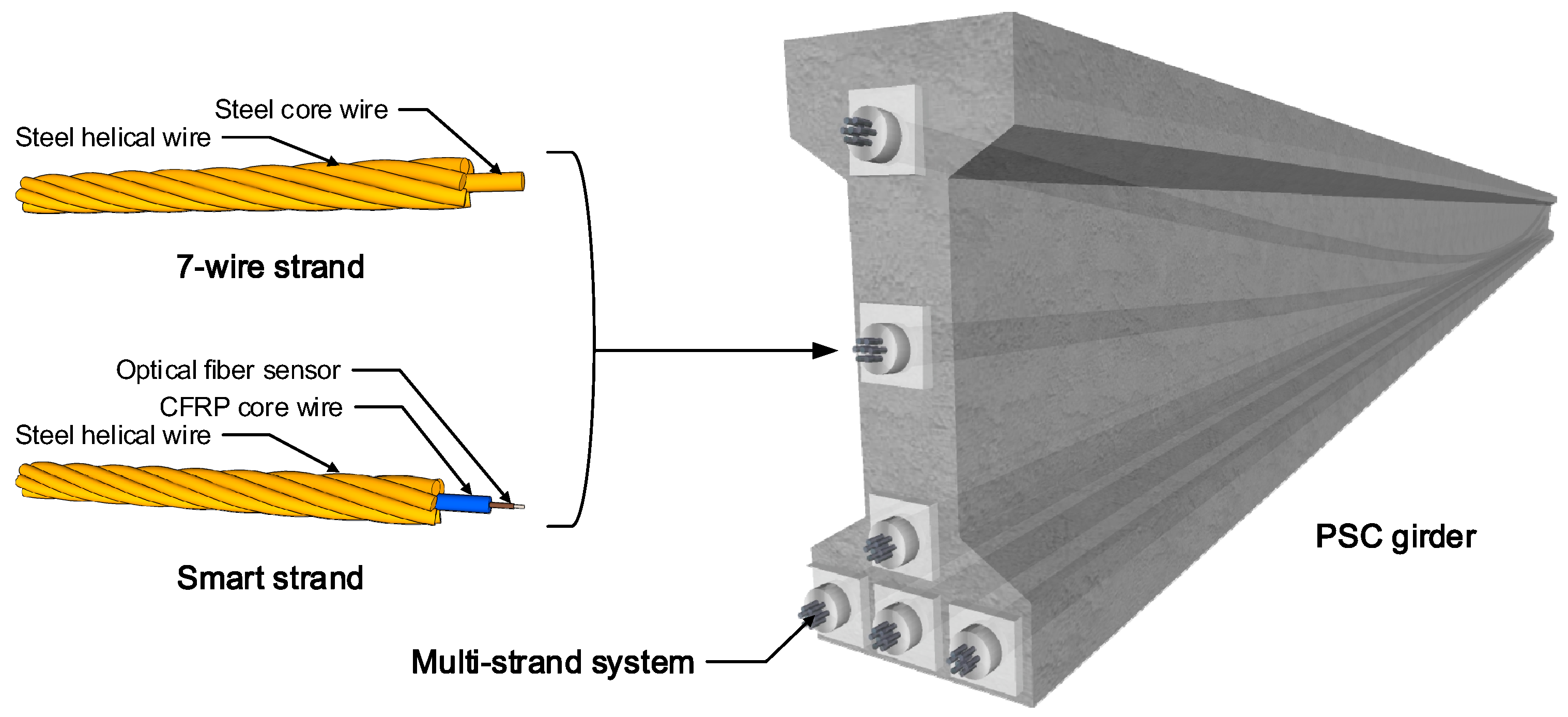

Prestressed strand is a high-strength steel cable made of multiple wires twisted together. It’s used in prestressed concrete systems to help structures withstand heavy loads, reduce cracking, and allow for wider spans with fewer columns or supports

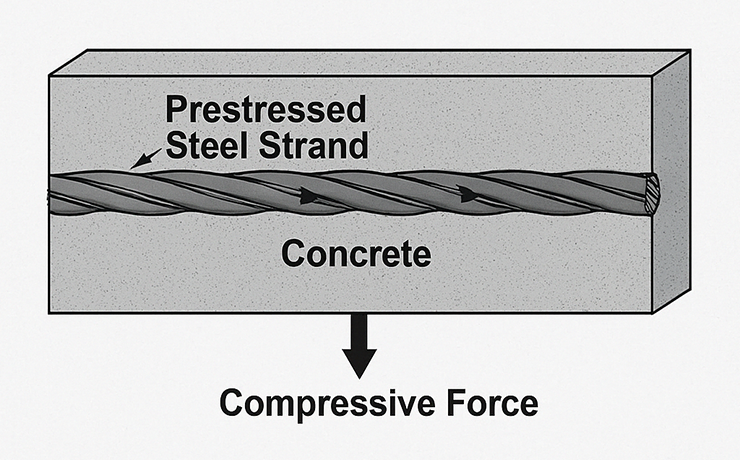

How Prestressed Concrete Works

Concrete is strong in compression but weak in tension. Prestressed strand compensates for this by applying compressive forces to the concrete, either before or after the concrete is poured

Pre-tensioning: The strand is tensioned before casting the concrete

Post-tensioning: The strand is tensioned after the concrete has cured, typically through ducts inside the concrete

Where Prestressed Strand Is Used

Parking structures

Commercial and residential slabs

Bridges and overpasses

High-rise buildings

Industrial warehouses

Tunnels and infrastructure projects

Main Advantages of Using Prestressed Strand

Higher Tensile Strength✅

Strands resist loads up to 1860 MPa — much stronger than standard rebar.

Minimal Cracking✅

Internal compressive force reduces surface cracks significantly

Longer Spans Without Columns✅

Ideal for open spaces in malls, basements, or parking lots

Lighter Structures✅

Less concrete and steel are needed — saving weight and cost

Increased Durability✅

Better resistance to corrosion, deformation, and seismic activity

Faster Construction Time✅

Prefabricated prestressed components speed up on-site execution

Comparison Table: Strand vs Traditional Reinforcement

Feature | Prestressed Strand | Rebar (Conventional Steel) |

|---|---|---|

Tensile strength | Very high (up to 1860 MPa) | Moderate (up to 500 MPa) |

Crack control | Excellent | Limited |

Span capabilities | Long spans possible | Short spans only |

Weight of structure | Lighter | Heavier |

Cost-efficiency | Higher savings in materials | Higher consumption |

Seismic performance | Strong | Moderate |

Burj Khalifa, Dubai

The Burj Khalifa, the tallest building in the world, is one of the most iconic examples of PC strand (prestressed concrete strand) used in modern construction. The project utilized a post-tensioning system with PC strands to reinforce concrete slabs and optimize the structural performance of the tower

:The use of prestressed strands in Burj Khalifa resulted in

High structural resistance against wind and seismic forces✔

Fewer columns, allowing for more open and functional interior spaces✔

Faster construction time and enhanced overall quality✔

Sault Ste. Marie International Bridge (Michigan, USA – Ontario, Canada)

A key transport link built with post-tensioned prestressed concrete elements for long-term performance

Precast Segmental Bridges in Europe & Asia

Many large-scale bridges in Europe, China, and the Middle East use prestressed segments for faster and more efficient construction

Conclusion

Prestressed strand systems are revolutionizing concrete construction by offering higher strength, better durability, and cost savings. They are essential for modern engineering projects like bridges, towers, slabs, and infrastructure where performance and safety are critical

?Want to build stronger, lighter, and more efficient structures

Prestressed strand is the smart choice